CAIRO 3A INVESTED EGP3bn IN POULTRY SECTOR IN THE PAST 5 YEARS, THE AUTOMATED SLAUGHTERHOUSE INCLUDED

Cairo 3A Group forecasts EGP1bn sales by the end of this year and to achieve a 16% market share out of Egypt’s total frozen chicken market sales, jumping to the ranks of Egypt’s major players in food industries. Additionally, poultry manufacturers with the same trademark are expected to achieve up to EGP100mln sales during the same period and to grab a market share of 3% although they started the business just one year ago.

The sales results were announced in official statements by Cairo 3A Group officials, in light of the visit of a delegation of journalists and media representatives to the group’s automated slaughterhouse in the Regwa area on the Cairo-Alexandria Desert Road. The visit was arranged to update the visitors about the role of the slaughterhouse in providing the best poultry products to the local market in line with the state’s directions to provide affordable poultry protein with the application of the highest standards of environment and food safety. The guests were received by Ibrahim Wagdy, Deputy CEO of Cairo 3A, and a group of employees in charge of the slaughterhouse.

The slaughterhouse is located in the Regwa area, on the Cairo-Alexandria Desert Road, and extends over an area of 7 acres, in addition to including the latest equipment and devices supplied by major international companies to ensure the highest quality in compliance with environmental standards and food safety. The slaughterhouse is expected to provide 20,000 chickens to the local market in the span of the upcoming three years, with an average daily production ranging from 50 to 60 thousand chickens.

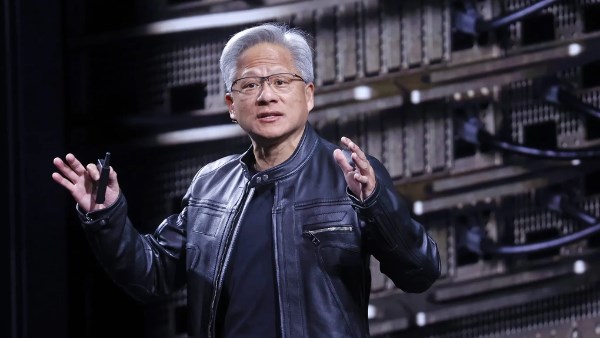

Work inside the automated slaughterhouse

During the tour, Cairo 3A Group officials explained the stages of work inside the automated slaughterhouse, starting with receiving live chickens from the company’s farms, they are transported in equipped cars belonging to Cairo 3A for Transportation company, and when they reach the slaughterhouse, they are entered into the waiting room at a temperature of 25°C for an hour following the animal welfare measures. This process is done to provide an appropriate atmosphere and conditions to avoid any physiological change or tension resulting from the transportation process. After the poultry is slaughtered according to Islamic law, cleaned from the effects of slaughter, and cooled by the latest advanced methods to reduce the water inside to ensure its quality, the poultry moves to the cutting and packaging stage. After packaging, the final products are stored in chill rooms to preserve the fat and vitamins of the chickens.

The automated slaughterhouse of Cairo 3A Group applies the highest standards of food safety, as it follows the biosecurity system with the latest sterilization systems before entering the slaughterhouse and automated packaging of products to prevent human contact. Moreover, veterinarians supervise all production stages to ensure the product's validity, considering the possibility of some diseases that do not appear on live chickens but can be detected after slaughter. Consequently, the slaughterhouse is among the top 3 approved slaughterhouse by the Food Safety Authority and is in included in the Authority's white list.

Environmental standards

The automated slaughterhouse also takes into account environmental standards and cares about waste recycling, where slaughter waste is recycled in laboratories equipped to extract animal protein used as food for fish farms after conducting analyzes for it at the Ministry of Health. At this stage, 7 to 8 tons of animal protein are extracted per day. Moreover, wastewater is also treated for use in irrigating the surrounding agricultural land, after conducting water analyzes to ensure its suitability for agricultural use. Because of these elevated standards, the slaughterhouse obtained ISO 22000 - 9001 - 14001 - 45000 certifications.

Ibrahim Wagdy, Deputy CEO of Cairo 3A Group, said that Shahd Chicken products succeeded in achieving record sales during the first 8 months of this year, with a growth rate of 26% over the same period last year, thanks to the brand’s high quality and reasonable price compared to the prices in the local market. This is due to the Group’s establishment of an integrated project for poultry production that includes the largest poultry farm with a production capacity of 60 million birds annually, in which the Hubbard Efficiency Plus chickens - the latest poultry breed of the Hubbard family - are raised. This breed is known for giving the highest productivity and the best quality whether live, frozen, or breaded chicken.

He added that Cairo 3A Group provides integration in all links of the poultry production chain, where poultry is raised from the generation of grandparents and mothers to chicks, which are fed with the finest types of 100% vegetable feed through the group’s feed factory in Sadat City. The breed that is raised is characterized by an increase in the breast’s meat, which leads to an increase in the percentage of the final amount of meat produced after slaughter, in addition to the strong bone structure, that bears this amount of meat without internal complications for the chicken. Moreover, the withdrawal period from the chicken is taken into account to be 15 days before the bird leaves the farm to ensure the consumer receives a product that is free of any antibiotics.

Finally, Wagdy stressed that Cairo 3A Group applies the highest standards of food safety, under the supervision of the relevant authorities and ministries, which carry out periodic follow-ups on all production stages and ensure their compliance with the specifications of animal welfare standards.

The largest national entity in the food industry sector

Cairo 3A, Egypt’s biggest national entity in the food industries sector, has several subsidiaries working in food industries in general, as they managed to export their products abroad. The company was established back in 1981 and started its business as a player in agriculture and commodities trading. Backed by a clear vision, Cairo 3A for Poultry sought to increase its investments by means of incorporating new companies, such as Cairo 3A for Poultry, which was established back in 2018, or acquiring existing national companies, such as the National Co. for Maize Products, Pyramids Poultry and Egyptian Starch and Glucose.

-1120252475029447.jpg)